Partition OXO

Digital Fabrication: The Future of Craftsmanship

Craftsmanship in architecture has become increasingly difficult to realize with cost, time constraints, and lack of skilled craftsmen. Leveraging digital fabrication, a plethora of unique and exciting forms can be explored at a high level of detail. This provides the perfect opportunity to pay homage to traditional craftsmanship and joinery.

The popularization of open concept design created the opportunity to look at historic joinery and screening methods as a device to divide up space. Ranging from the partitions found in midcentury houses to the celebration of joinery found in Japanese buildings, there are many precedents to examine when developing a partition concept.

Learning from Japanese Joinery techniques

The history of traditional Japanese joinery is a testament to the idea that structure can be beautiful, elegant, and intelligent. For centuries, Japanese builders relied on a profound understanding of wood physics to construct magnificent temples and homes without a single nail or screw. This philosophy, rooted in mokkō (woodworking), centers on creating lasting, resilient wood connections through ingenious fittings.

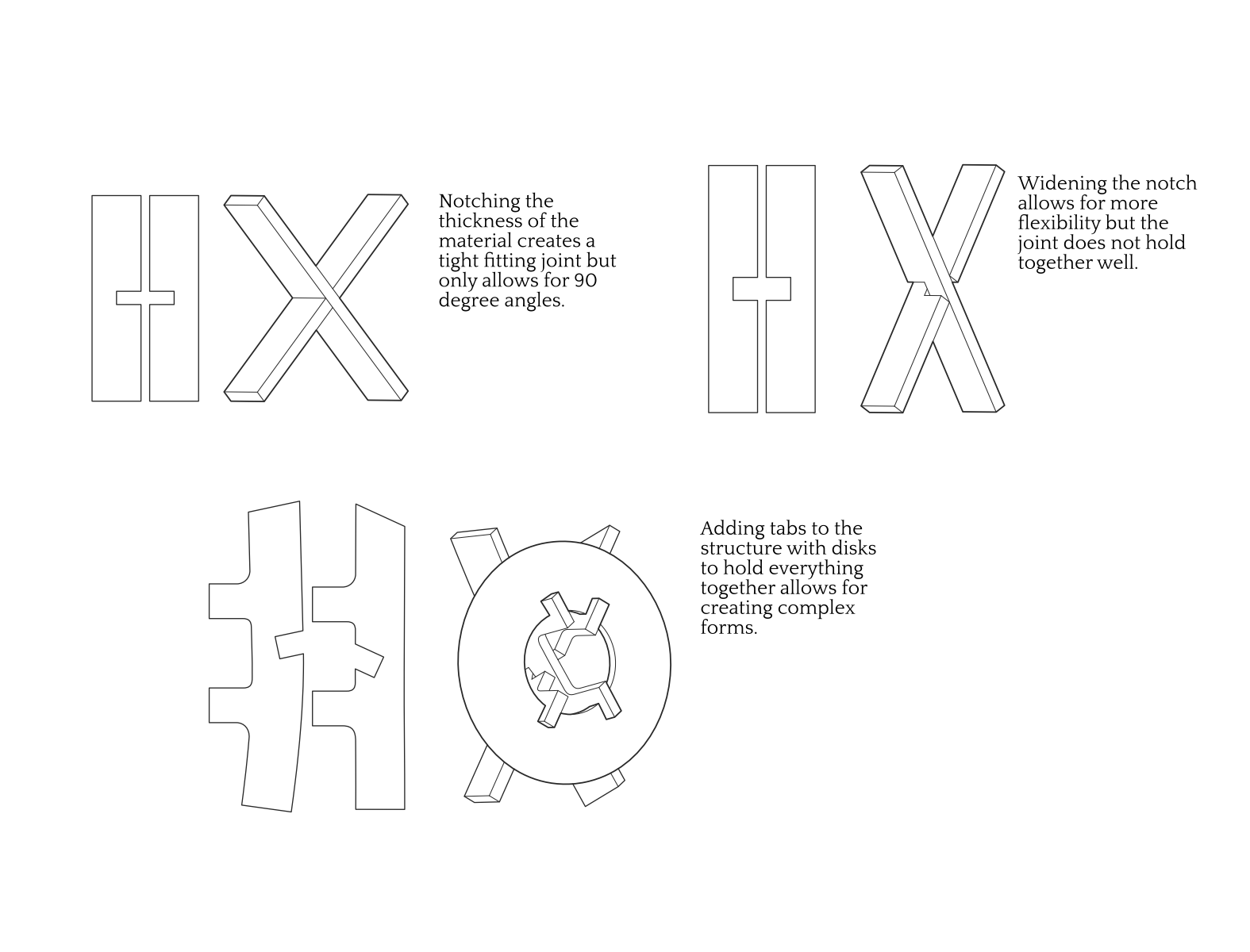

The core of this tradition lies in tsugi and shiguchi techniques for joining. These techniques require precision to create connections so tight that they can withstand shear and tension forces. Beyond their structural integrity, they offer exceptional aesthetics through showcasing a material’s structural abilities.

A Modern Approach

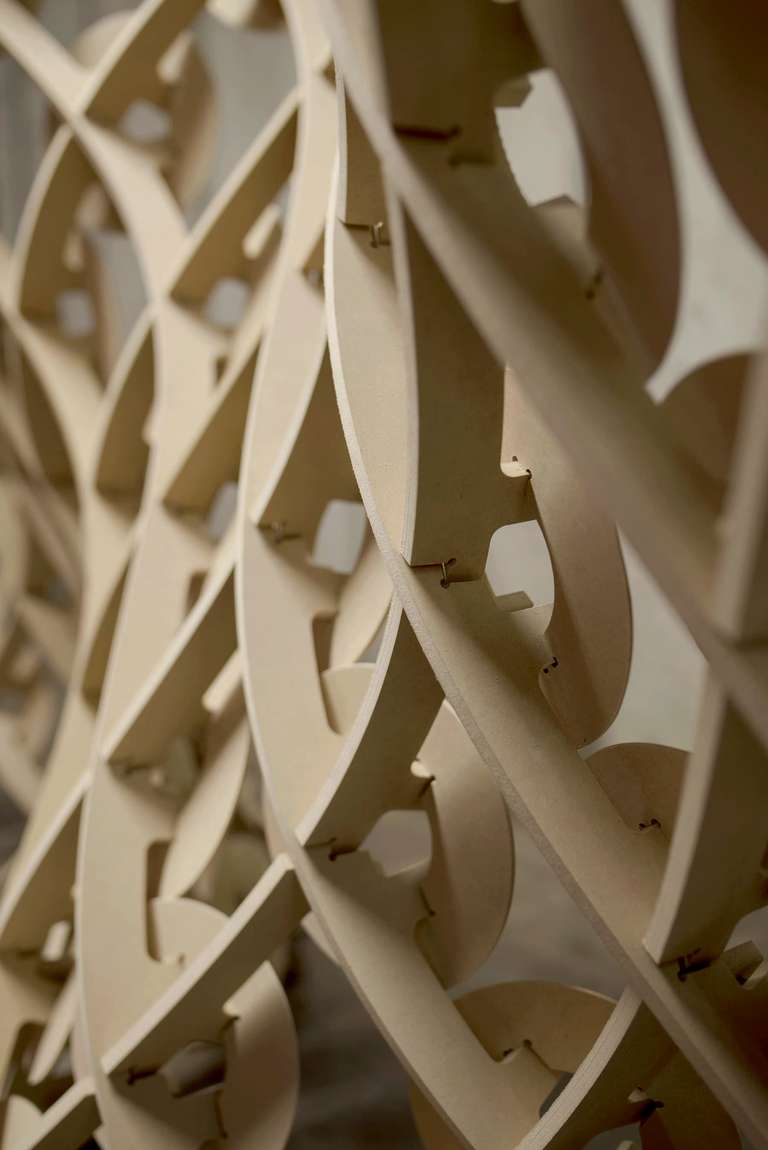

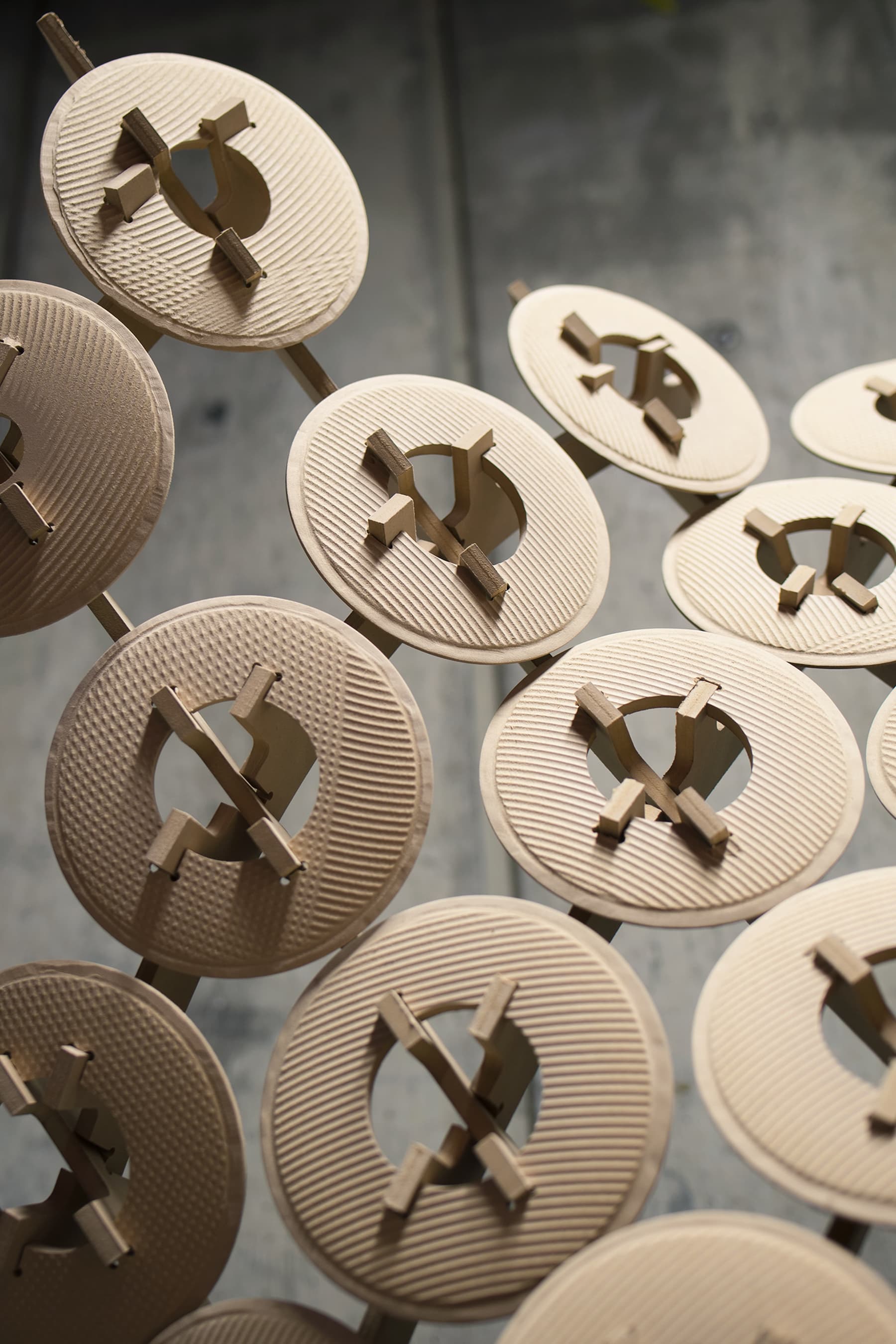

Through the historic examples, a system was developed where diagonal cross-bracing was used to provide the backbone of the partition. Discs slot in to lock in the cross-bracing and give the partition a surface quality for privacy. Through parametric modeling, all of the elements can be quickly edited and unique outputs generated all through the manipulation of a few inputs. The resulting 3D model feeds directly into being laid out for CNC milling (Computer Numerical Controlled Router). All that has to happen is the desired sheet good has to be placed on the router and the generated program run. This adaptable approach allows for many different outputs based on where the partition is needed and the form that it is needed to be in. The methodology of Partition OXO can be applied in many exciting ways to make crafting beautiful, intricate pieces easily.